blog

..it all started in 1998…

Scentsational is an American Dream that came true. The company began making handmade soaps, with the first bar coming out of the Morrison’s family garage. The soaps were in such demand, the family decided to open a small store in downtown Venice, Florida. One day, a lady on vacation stopped in and purchased a few bars of soap and went on her way. Turns out, she was the head buyer at a large retailer. She was the catalyst for Scentsational’s first big buy! To fulfill that first order, the entire family, neighbors, friends, and anyone willing to help, assisted. When we say it took a village, you better believe it. The first order was followed by a reorder, and soon after, candles were added to the growing business. Our high quality scented candles became so popular, that they are now our main focus.

Continued growth pushed Scenstational out of the small downtown Venice location and into an actual production facility. 730 Commerce Drive has been home for quite some time now. The building itself has just undergone a substantial transformation, growing to nearly 100,000 square feet. Even with the growth, the business model has stayed the same for the past 25 years; making amazing candles at affordable prices, that’s precisely what we achieve daily. Taking the time to reflect on the past couple decades of business, it’s important to acknowledge the people who have made it all possible.

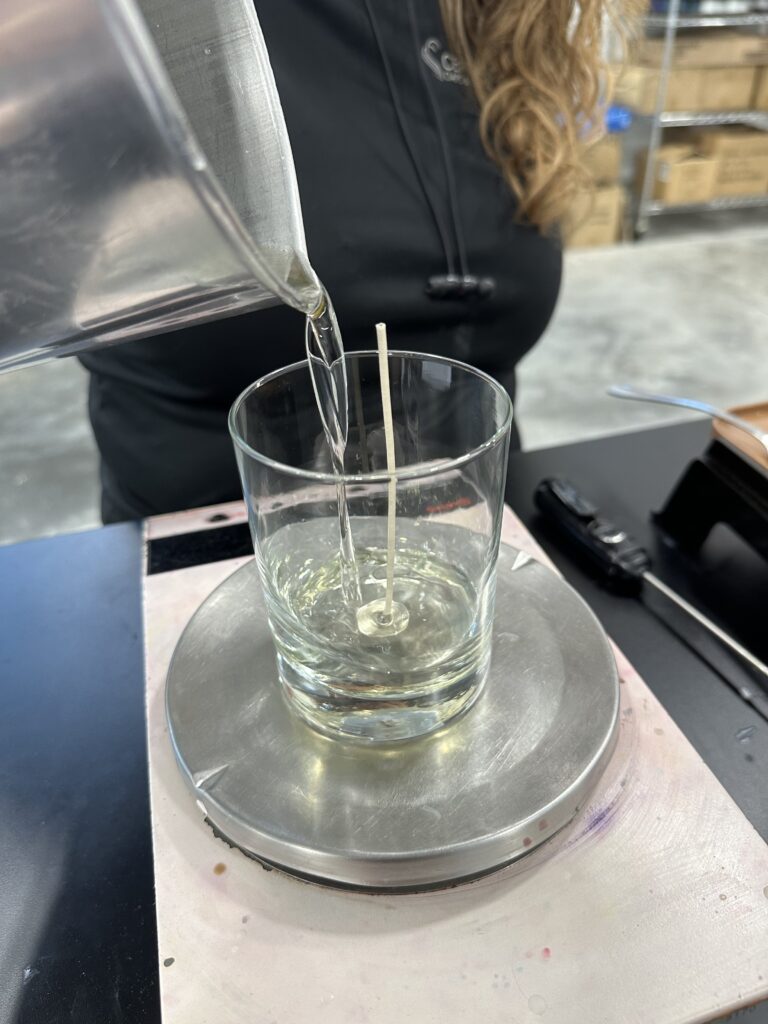

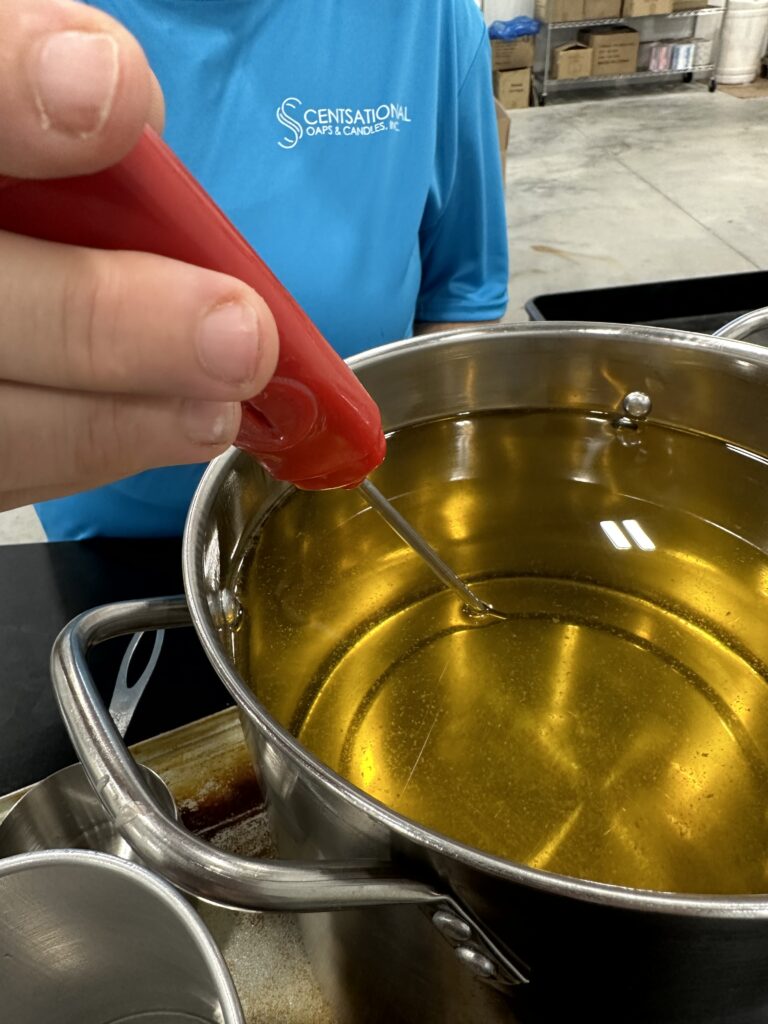

For our brand, it begins with research & development(R&D) in the lab. Before a candle is put into production, our R&D team will extensively test our exclusive soy based wax blends and fragrance loads. If you ask me why our candles are the best, I’ll always say we have a superior wax. You want to know the secret? I’ll bet, but that one is staying in the family.

The R&D team tests every single fragrance that comes through the door. They also create wax colors for a wide array of customers, working endless hours making sure we pass the most stringent testing requirements to guarantee what you’re burning in your home is safe.

Prior to the candles actually being poured, nearly all of our vessels are decorated. We like to refer to ourselves as the Willy Wonka factory of candle manufacturing. We’re able to do it all in house; from painting the vessels, plastic sleeves, screen printing, and of course, labeling. The Wooden Wick wicking machine is a fairly recent addition as well. All of these capabilities help the business control cost and lead times.

Then we get to the fun stuff. Watching the vessels filled with scented wax travel along the line is truly the best part of the process. Every day a wonderful fragrance fills the factory. Even with all the machines, it takes about 10-12 people, per line, to run production. Each person is an integral part of the process. These team members are averaging 18,000-25,000 candles per day, per line.

I cannot leave out the team members behind the scenes as well. Human resources, Accounting, Account Executives, Artwork/Design, Purchasing, Invoicing, it takes many hardworking individuals to make all the wheels turn so we can continue our forward motion. Our team is the village, we have one goal; to bring you the best candles – proudly poured in the U.S.A.

If you ever make the trip to Venice, Florida please stop in our factory store. Cathy is our receptionist and will gladly tell you all about her pride and joy, her store. We would love to have you visit our home and meet our family. Thank you for the continued support over the past 25 years. We couldn’t have made it here without you!

Scentsationally,

JaNiece Cranmer

President, Scentsational Candles